In the articles related to the introduction of flexible packaging and rigid packaging, we mentioned the properties, advantages and disadvantages of each type of packaging. In the following, we are trying to address the new methods of food packaging that the packaging industry has provided to increase the amount of storage or easier transportation of products. One of these approaches is the controlled atmosphere (CA) method. This method can play a big role in maintaining and exporting food from any country. Stay with Karya Polymer, a polymer company active in the field of flexible packaging, to learn more about this method.

An overview of the new approach in the packaging industry

Controlling the atmosphere of the product storage area is one of the most effective methods that can meet the needs of manufacturers regarding product packaging.

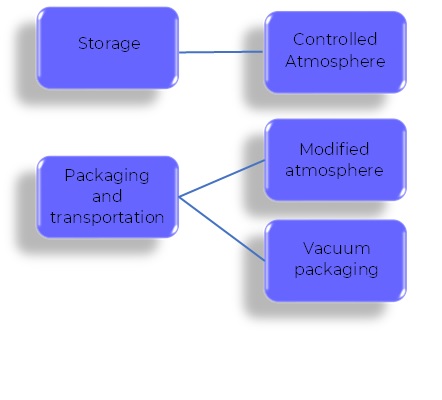

The controlled atmosphere method is the preferable approach to product storage.

If the desired product is to be stored, the controlled atmosphere method is preferable to other methods. Modified atmosphere methods (MAP) and vacuum packaging methods will be more suitable options for packaging and transportation goals.

If packaging and transportation is a priority for the manufacturer, two modified atmosphere methods (MAP) and the vacuum packaging method will be more suitable options.

Modified atmosphere methods (MAP) and vacuum packaging methods will be more suitable options for packaging and transportation goals.

In the following article, we will explain the advantages and characteristics of the controlled atmosphere (CA) method.

Controlled Atmosphere method

For a better understanding of the controlled atmosphere method, it is better to investigate the following points:

• Target

• How does it work?

• Where does it run?

• How to control the atmosphere inside a tank?

Target

The purpose of this method is to increase the shelf life of fresh agricultural products while maintaining the initial quality.

How does it work?

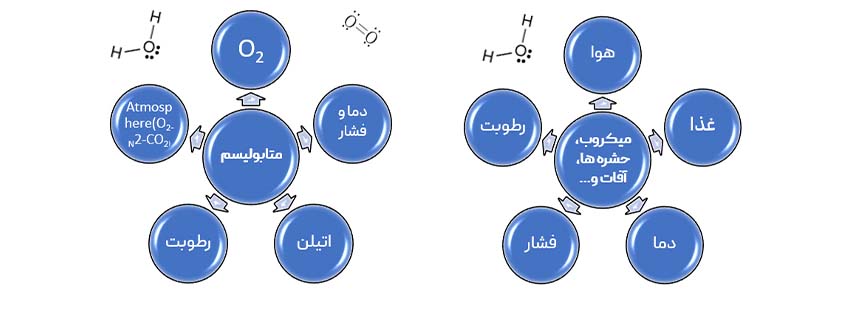

Oxygen decrease

Setting the composition of the ambient atmosphere

Temperature and humidity control

Where does it run?

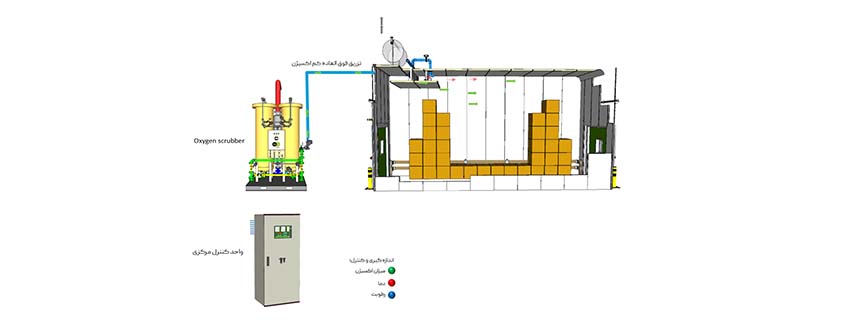

Mainly, this method is implemented in the chambers that are considered for this purpose in cold stores. These chambers have insulating walls against heat and permeable against gases and moisture.

Controlling the atmosphere inside the tank

In this method, the atmosphere of the storage tank is changed according to the product specifications, which can be summarized as below:

- The possibility of growth and life because of environmental and external factors is reduced to a minimum.

- The speed of chemical reactions should be minimized by not providing the requirements for the continuation of chemical reactions in the product.

This method is implemented by controlling the following:

• Decrease in oxygen

• Increase in carbon dioxide

• Temperature, pressure and humidity control

Products that can be preserved by the controlled atmosphere method

A wide range of agricultural products can be stored and maintained with this method,

- Fruits

- All kinds of vegetables

- Dried fruit

- Tobacco, sprouts, rice and fodder

Controlled items of products that guarantee the maintenance of quality components:

- Total number of live microbes, mold and yeast

- Mushrooms

- Moisture percentage

- Percentage of weight loss

- Color

- Protein percentage

- Acidity

- Glucose level

Advantages of controlled atmosphere (CA) method

- Keeping products up to 4 times longer than other conventional methods

- No use of chemicals and toxic substances

- Accurate and sensitive monitoring system

- Keeping humidity constant and preventing mold and fungus growth

- Reduce shipping costs by providing additional storage time

- The high degree of compatibility of domestic and export products of Iran with this technology

- Reducing damage and product wastage

- Reducing energy consumption (not using refrigeration and thermal processes)

- Safe and environmentally friendly

Required information for technology deployment

- Products that can apply technology

- Minimum and maximum shelf life of each product

- Atmosphere formula and optimum temperature and humidity for keeping each product

- Required storage space

- Exportable agricultural product or not exportable

- Arranged equipment

Some technical points in the controlled atmosphere (CA) storage method

- In today’s technologies, the highest quality and long history is related to this method.

- In Iran, most of the stored fruits have fungal and mold contamination.

- Fruits should be stored for a maximum of one week after harvesting.

- The main factor in reducing the weight of products after cooling is the humidity of the surrounding air.

- Controlled air can be done in halls that are impermeable to gases and have oxygen, carbon dioxide, and ethylene measuring devices.

Equipment required to use the CA method:

- Rooms with controlled air

- Various chemicals

- Separator

- Converter device

- Gas generators

- Recording devices (writing device)

- Fan

Controlled air rooms:

- Capacity:

The capacity of the rooms is usually from one hundred tons to 1000 tons for each product.

- Gas Sealing:

The building of the rooms to maintain the controlled air should be designed in such a way that it can have the proper gasification to maintain the composition of the air inside the room.

Properties of suitable materials for gasification:

- Do not allow gas to enter them

- Do not smell

- To be resistant to microorganisms and moisture

- It is easy to install and repair them.

- To withstand mechanical shocks.

- Do not be flammable or incendiary.

- Maintain their properties against changes in temperature, relative humidity and pressure inside the room.

Oxygen reduction with converters:

Converters are used to reduce oxygen to 2 to 4 volume percent in 2 to 3 days. Converters work based on the consumption of oxygen by burning hydrocarbons or combining oxygen with hydrogen obtained from the decomposition of ammonia (NH3).

Atmosphere control methods:

- Static: The amount of O2 and CO2 and the details of the chamber atmosphere are kept constant during the storage period.

- Dynamics: The amount of O2 and CO2 in the chamber changes during the storage period according to the data received from the recording device or the biological process of the product.

Gas generators:

There are two types of generators:

- The generator with an open circuit that takes the outside air, and after burning the oxygen and stabilizing the carbon dioxide, sends the gas mixture into the room with a fan.

- The generator with a closed circuit that circulates the air inside the storage room gradually reduces its oxygen, removes carbon dioxide and circulates the obtained gas inside the room until the desired composition is obtained.

Various chemicals:

- Various chemicals (Potassium carbonate, Sodium hydroxide, Ethanolamine, calcium hydroxide, etc.) are used to absorb carbon dioxide.

- Separator (one, two or three) ethanolamine

- Potassium carbonate separators

- Dry calcium hydroxide separator

Recorder (writer) devices:

- The preservation factors (temperature, relative humidity and gas mixture) are controlled twice at the beginning of the day and then daily by direct reading or by using recording devices.

- The quality of stored products should be controlled by devices according to a schedule at regular intervals.

Fans and blowers:

Whenever you want to end the storage with controlled air, open the doors of the room and let the fans work for one to two hours. In this case, the excess carbon dioxide is dispersed, the oxygen in the air is balanced with the surrounding air and the environment for entering and workers are safe without using a protective mask.