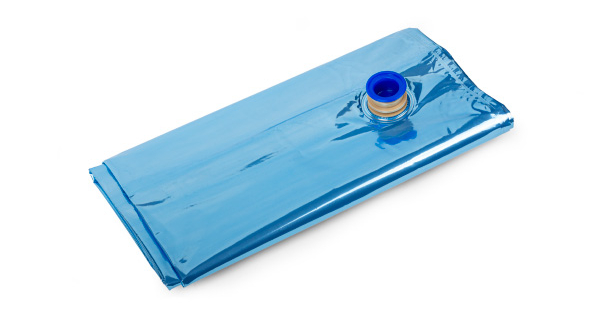

What is the Aseptic bag?

Aseptic packaging is the process of preventing microorganisms from entering a package during and after packaging.

Aseptic processing is a processing technique in which commercially thermally sterilized liquid products (typically food or pharmaceutical) are packaged into previously sterilized containers under sterile conditions to produce shelf-stable products that do not need refrigeration.

Aseptic packaging material has to assure sterile conditions within the package and protect the product from physical damage and maintain the quality of the product inside the packaging.

Aseptic processing involves three primary steps:

- Thermal sterilization

- Sterilization of the packaging material

- Maintenance of sterility during packaging

In the food industry, aseptic packaging bags are divided into high-volume aluminum-plastic composite aseptic bags (5 – 200 L) and low-volume co-extruded film aseptic bags (200- 500 ml). They are perfect packaging materials for juices, jams, dairy products, and other foods.

Aseptic packaging materials

Several materials are layered together to provide the level of protection required for aseptic packaging standards, including:

- Polyethylene is used as a barrier on the inner and outside of aseptic packaging. These layers protect against moisture entering or exiting the container.

- Film oil helps preserve the product by keeping out light and oxygen.

Aseptic Bag Application:

Aseptic bags are used for various food products, such as tomato concentrate, paste, and pulp, fruit and vegetable juices, concentrates and diced fruits, and sauces, dairy products, and liquid eggs. They are also used in the pharmaceutical industry to ensure that medications aren’t polluted with harmful bacteria. They are suitable for aseptically processed products that must be filled, stored, and distributed at room temperature. They are a convenient and efficient way to transport large quantities over long distances. Aseptic bags are also suitable for efficiently filling and distributing new, extended shelf life (ESL) processed food and non-food products for better preservation.

Aseptic Bag Advantages:

- Increased shelf life

- Maintains quality of contents

- Less packaging waste

- Less product wastage

- Energy efficiency

- Resource efficiency

- Economical solution for packing and transport of liquid foods in large quantities

- Reduce transportation costs

- Eco-friendly

About Aseptic Bags (Bag in Box):

Karya Polymer Aseptic Packaging (Bag in Box) is perfect for extending the shelf life of liquid or semi-liquid food or industrial products to store and transport liquids and processed products without the need for preservatives at room temperature. Karya Polymer Aseptic packages are made of multilayer metalized films with different materials; the number of layers and their thickness varies depending on the product. The strength of the bag layer prevents air from entering the product and protects it from direct contact with the sun’s rays. Aseptic packaging protects the product from the ingress of foreign matter. As a result, the packaged contents’ nutritional value, taste, flavor, and color do not change.

Features:

- Extend the shelf life of food up to 6 months

- Reduce distribution and shipping costs

- Maintain product quality without the need for preservatives

- Ability to sterilize products at the same time as packaging

- Resistance to high temperatures.

Applications:

- Tomato, vegetable, and fruit concentrate.

- Juice, distillates، mineral water, fountain, syrup, and milk

- Dried milk, dough, pulp, and pudding

- Pharmaceutical raw material

What is Vacuum bag

What is Vacuum bag

Leave a Reply

Want to join the discussion?Feel free to contribute!